Ideal versus standard PID form

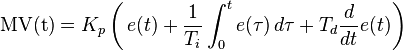

The form of the PID controller most often encountered in industry, and the one most relevant to tuning algorithms is the standard form. In this form the  gain is applied to the

gain is applied to the  , and

, and  terms, yielding:

terms, yielding:

gain is applied to the

gain is applied to the  , and

, and  terms, yielding:

terms, yielding:

where

is the integral time

is the integral time is the derivative time

is the derivative time

In this standard form, the parameters have a clear physical meaning.

In particular, the inner summation produces a new single error value

which is compensated for future and past errors. The addition of the

proportional and derivative components effectively predicts the error

value at  seconds (or samples) in the future, assuming that the loop control

remains unchanged. The integral component adjusts the error value to

compensate for the sum of all past errors, with the intention of

completely eliminating them in

seconds (or samples) in the future, assuming that the loop control

remains unchanged. The integral component adjusts the error value to

compensate for the sum of all past errors, with the intention of

completely eliminating them in  seconds (or samples). The resulting compensated single error value is scaled by the single gain

seconds (or samples). The resulting compensated single error value is scaled by the single gain  .

.

seconds (or samples) in the future, assuming that the loop control

remains unchanged. The integral component adjusts the error value to

compensate for the sum of all past errors, with the intention of

completely eliminating them in

seconds (or samples) in the future, assuming that the loop control

remains unchanged. The integral component adjusts the error value to

compensate for the sum of all past errors, with the intention of

completely eliminating them in  seconds (or samples). The resulting compensated single error value is scaled by the single gain

seconds (or samples). The resulting compensated single error value is scaled by the single gain  .

.

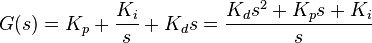

In the ideal parallel form, shown in the controller theory section

the gain parameters are related to the parameters of the standard form through  and

and  .

This parallel form, where the parameters are treated as simple gains,

is the most general and flexible form. However, it is also the form

where the parameters have the least physical interpretation and is

generally reserved for theoretical treatment of the PID controller. The

standard form, despite being slightly more complex mathematically, is

more common in industry.

.

This parallel form, where the parameters are treated as simple gains,

is the most general and flexible form. However, it is also the form

where the parameters have the least physical interpretation and is

generally reserved for theoretical treatment of the PID controller. The

standard form, despite being slightly more complex mathematically, is

more common in industry.

and

and  .

This parallel form, where the parameters are treated as simple gains,

is the most general and flexible form. However, it is also the form

where the parameters have the least physical interpretation and is

generally reserved for theoretical treatment of the PID controller. The

standard form, despite being slightly more complex mathematically, is

more common in industry.

.

This parallel form, where the parameters are treated as simple gains,

is the most general and flexible form. However, it is also the form

where the parameters have the least physical interpretation and is

generally reserved for theoretical treatment of the PID controller. The

standard form, despite being slightly more complex mathematically, is

more common in industry.Reciprocal gain

In many cases, the manipulated variable output by the PID controller

is a dimensionless fraction between 0 and 100% of some maximum possible

value, and the translation into real units (such as pumping rate or

watts of heater power) is outside the PID controller. The process

variable, however, is in dimensioned units such as temperature. It is

common in this case to express the gain  not as "output per degree", but rather in the form of a temperature

not as "output per degree", but rather in the form of a temperature  which is "degrees per full output". This is the range over which the output changes from 0 to 1 (0% to 100%).

which is "degrees per full output". This is the range over which the output changes from 0 to 1 (0% to 100%).

not as "output per degree", but rather in the form of a temperature

not as "output per degree", but rather in the form of a temperature  which is "degrees per full output". This is the range over which the output changes from 0 to 1 (0% to 100%).

which is "degrees per full output". This is the range over which the output changes from 0 to 1 (0% to 100%).Basing derivative action on PV

In most commercial control systems, derivative action is based on PV

rather than error. This is because the digitized version of the

algorithm produces a large unwanted spike when the SP is changed. If the

SP is constant then changes in PV will be the same as changes in error.

Therefore this modification makes no difference to the way the

controller responds to process disturbances.

Basing proportional action on PV

Most commercial control systems offer the option of also basing the

proportional action on PV. This means that only the integral action

responds to changes in SP. The modification to the algorithm does not

affect the way the controller responds to process disturbances. The

change to proportional action on PV eliminates the instant and possibly

very large change in output on a fast change in SP. Depending on the

process and tuning this may be beneficial to the response to a SP step.

Sometimes it is useful to write the PID regulator in Laplace transform form:

Having the PID controller written in Laplace form and having the transfer function of the controlled system makes it easy to determine the closed-loop transfer function of the system.

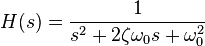

PID pole zero cancellation

The PID equation can be written in this form:

When this form is used it is easy to determine the closed loop transfer function.

If

Then

While this appears to be very useful to remove unstable poles, it is

in reality not the case. The closed loop transfer function from

disturbance to output still contains the unstable poles.

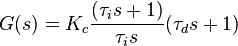

Series/interacting form

Another representation of the PID controller is the series, or interacting form

where the parameters are related to the parameters of the standard form through

,

,  , and

, and

with

.

.

This form essentially consists of a PD and PI controller in series,

and it made early (analog) controllers easier to build. When the

controllers later became digital, many kept using the interacting form.

Discrete implementation

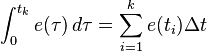

The analysis for designing a digital implementation of a PID controller in a microcontroller (MCU) or FPGA device requires the standard form of the PID controller to be discretized.[25] Approximations for first-order derivatives are made by backward finite differences. The integral term is discretised, with a sampling time  ,as follows,

,as follows,

,as follows,

,as follows,

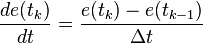

The derivative term is approximated as,

Thus, a velocity algorithm for implementation of the discretized PID controller in a MCU is obtained by differentiating  , using the numerical definitions of the first and second derivative and solving for

, using the numerical definitions of the first and second derivative and solving for  and finally obtaining:

and finally obtaining:

, using the numerical definitions of the first and second derivative and solving for

, using the numerical definitions of the first and second derivative and solving for  and finally obtaining:

and finally obtaining:

06.43

06.43

Unknown

Unknown

![u(t_k)=u(t_{k-1})+K_p\left[\left(1+\dfrac{\Delta t}{T_i}+\dfrac{T_d}{\Delta t}\right)e(t_k)+\left(-1-\dfrac{2T_d}{\Delta t}\right)e(t_{k-1})+\dfrac{T_d}{\Delta t}e(t_{k-2})\right]](https://upload.wikimedia.org/math/a/9/b/a9beb5ee392aa86e76d734e9e761b148.png)

Posted in

Posted in